[vc_row type=”in_container” full_screen_row_position=”middle” scene_position=”center” text_color=”dark” text_align=”left” overlay_strength=”0.3″][vc_column column_padding=”no-extra-padding” column_padding_position=”all” background_color_opacity=”1″ background_hover_color_opacity=”1″ width=”1/1″ tablet_text_alignment=”default” phone_text_alignment=”default”][vc_column_text]

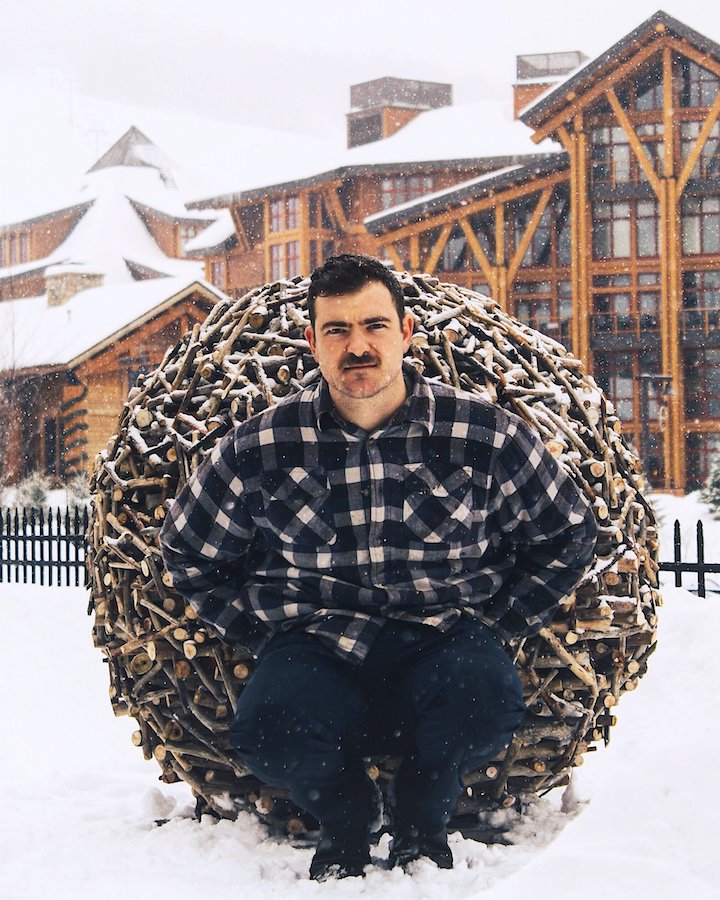

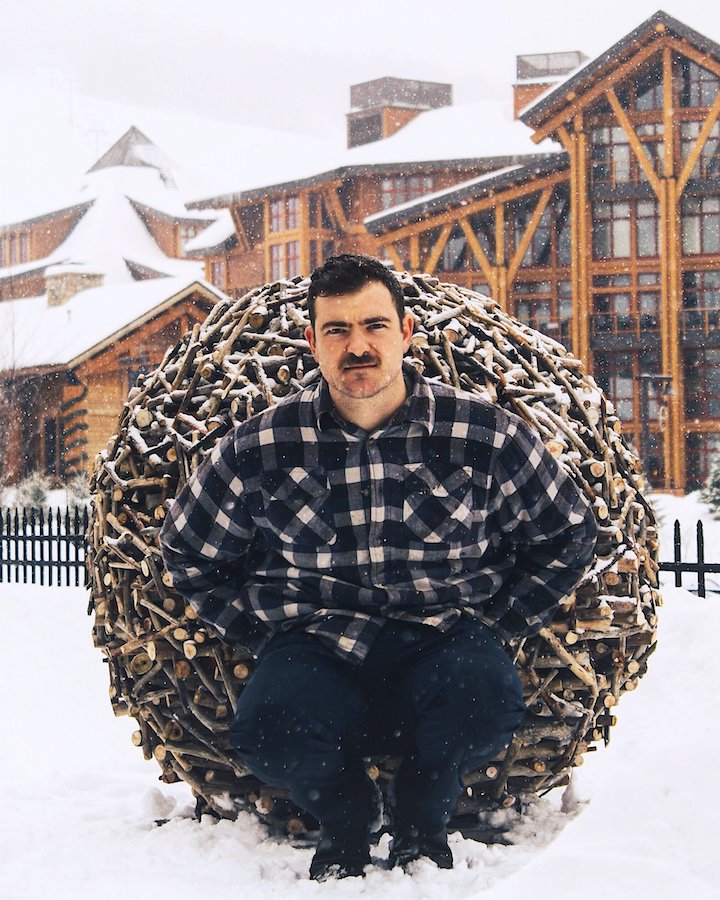

Meet Clay.

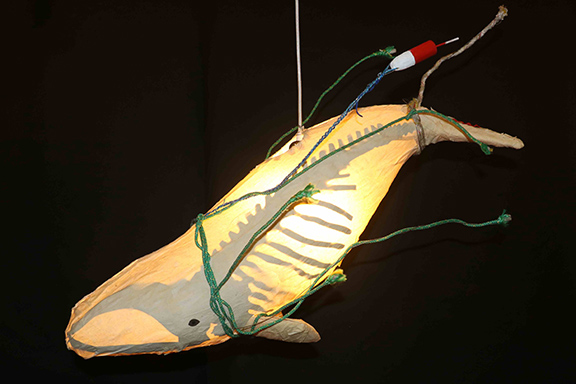

Clay Mohrman started playing with lighting and driftwood while he worked for an industrial light supplier in the greater Boston area. He was a hobbyist in those years, refining his craft and making one-off light sculptures for friends and family.

When Clay moved to Vermont, he rented a small studio on Pine Street. He meticulously sawed, sanded, and assembled his pieces with hand tools.

Despite growing interest in his light sculptures, Clay’s time-consuming, labor-intensive process prevented him from pricing his work to sell.

Clay knew he had a unique idea and that there was a market for his original, elegant work, but needed help turning his art practice into a sustainable art business.

Enter: Generator’s Jump/Start program.

Jump/Start is a business accelerator program developed by Generator in collaboration with LaunchVT. The 11-week program consists of weekly lectures on topics ranging from accounting, to intellectual property protection, to marketing. The program also facilitates in-depth tutoring with business professionals and mentors.

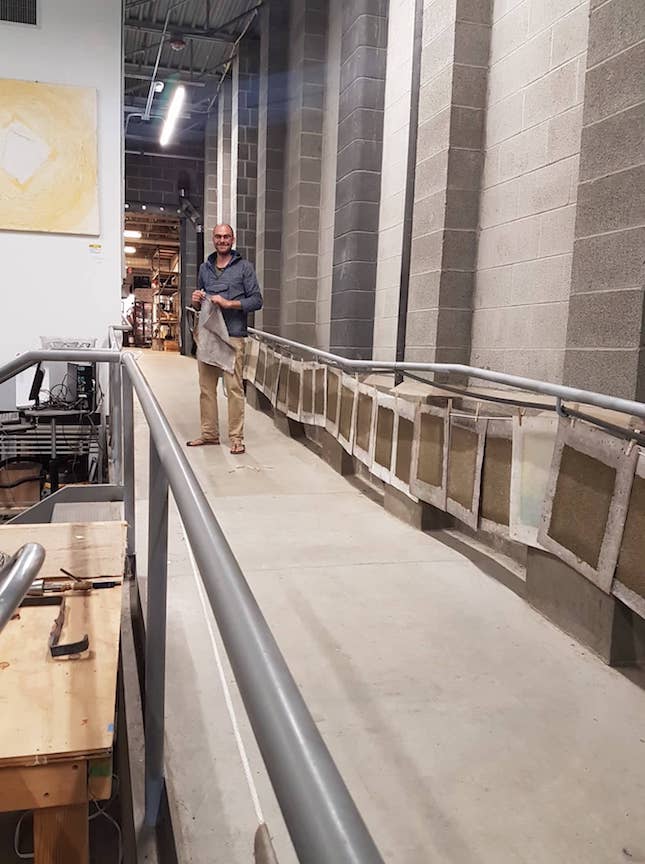

Clay and three other talented makers were given the use of free studio space, 24/7 access to Generator, a stipend, and free tool training classes to help them refine their product prototype.

“I couldn’t afford the kinds of woodworking tools I needed to be efficient, let alone a full wood shop, so having access to these things at Generator was amazing,” Clay said. “The pneumatic nail gun alone was a game-changer.”

Through the Jump/Start program, Clay received support in developing a foundation for his business, including bookkeeping, branding, pricing, scheduling, and more.

He received personal mentoring from Burlington’s lighting legend, Steve Conant.

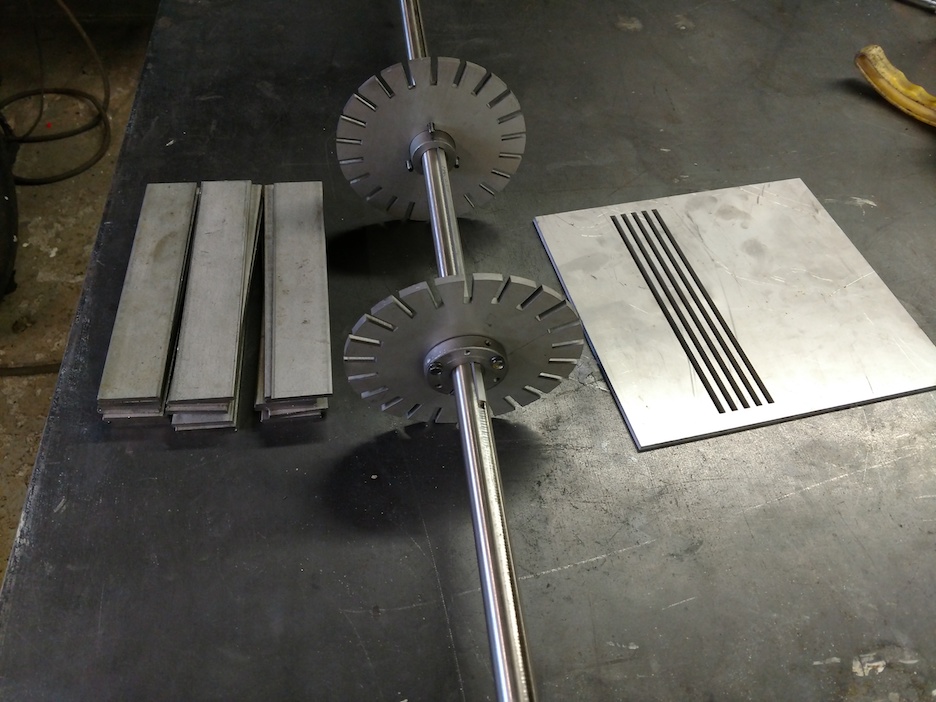

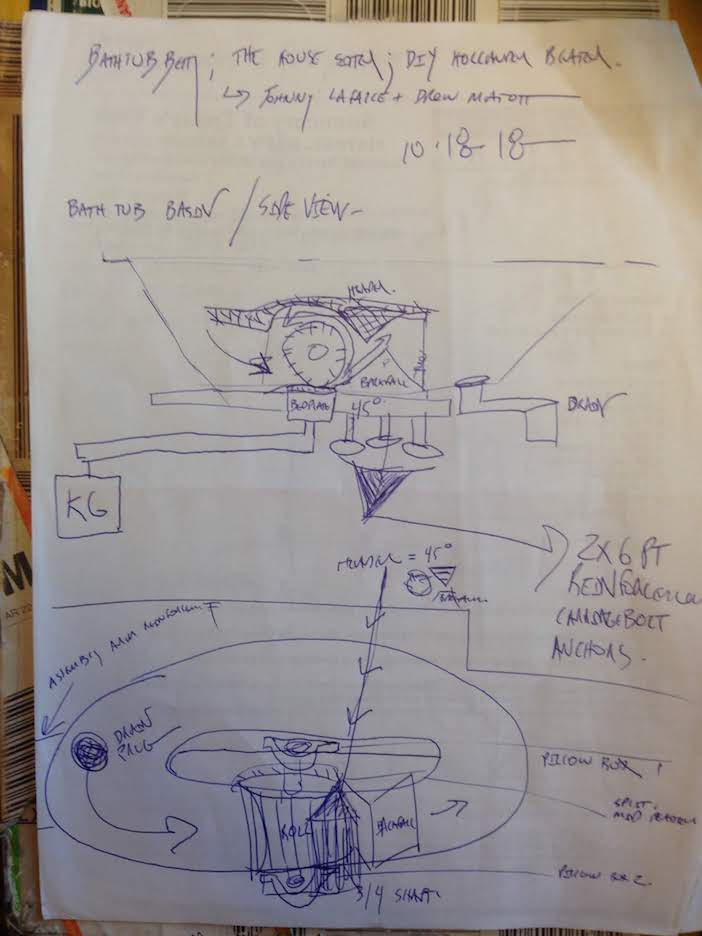

Clay also met with manufacturing experts M&E Design to improve his production process.

Clay cited Generator’s network of makers, entrepreneurs, and business professionals as a huge asset to his business.

“Starting a small business takes so much support, both emotionally and physically,” Clay said. “Having people around you going through the same process is invaluable.”

At the conclusion of the Jump/Start program, Clay became a Generator studio member.

“Generator keeps feeding me and my business,” Clay said. “I couldn’t be doing what I’m doing without the ongoing support and expertise of so many people here.”

Clay cites his participation in Jump/Start as the source of his confidence to launch his business, Clay Mohr Lighting.

The business has had numerous successes post-Jump/Start, including:

- month-long shows at Karma Birdhouse and Frog Hollow Gallery where his sales far exceeded expectations

- a 2018 Seven Daysies nomination for Best Sculptor followed up by a feature article in their “Nest” issue

- a collaboration with local musician Ivamae, Casting Coalescence, a traveling art installation that combines his lights with her music

- wholesale orders from shops as far away as Colorado

- and most recently, a winning bid for a light installation at Stowe’s Spruce Lodge for their Festival of Lights. Clay built and installed his largest piece yet — four feet in diameter. The piece was built in Generator’s common space.

“My business is continuing to evolve.

Jump/Start gave me a foundation to build on.”

—

With your support, we can help more people like Clay access opportunities to learn, create, and launch themselves and their businesses at Generator.

—

Will you make a year-end gift to support innovation?

[/vc_column_text][/vc_column][/vc_row][vc_row type=”in_container” full_screen_row_position=”middle” scene_position=”center” text_color=”dark” text_align=”left” overlay_strength=”0.3″][vc_column column_padding=”no-extra-padding” column_padding_position=”all” background_color_opacity=”1″ background_hover_color_opacity=”1″ width=”1/3″ tablet_text_alignment=”default” phone_text_alignment=”default”][/vc_column][vc_column centered_text=”true” column_padding=”no-extra-padding” column_padding_position=”all” background_color_opacity=”1″ background_hover_color_opacity=”1″ width=”1/3″ tablet_text_alignment=”default” phone_text_alignment=”default”][nectar_btn size=”jumbo” open_new_tab=”true” button_style=”regular” button_color_2=”Accent-Color” icon_family=”none” url=”https://generatorvt.com/donate/” text=”MAKE A GIFT” margin_top=”40″ margin_right=”30″ margin_bottom=”20″ margin_left=”30″][/vc_column][vc_column column_padding=”no-extra-padding” column_padding_position=”all” background_color_opacity=”1″ background_hover_color_opacity=”1″ width=”1/3″ tablet_text_alignment=”default” phone_text_alignment=”default”][/vc_column][/vc_row]